Understanding a 2 Float Switch Wiring Diagram is crucial for anyone setting up automatic water level control systems. Whether you're dealing with sump pumps, water tanks, or aquariums, knowing how to correctly wire two float switches can ensure your system operates safely and efficiently. This guide will break down what a 2 Float Switch Wiring Diagram entails and why it's so important.

What is a 2 Float Switch Wiring Diagram and How Do They Work?

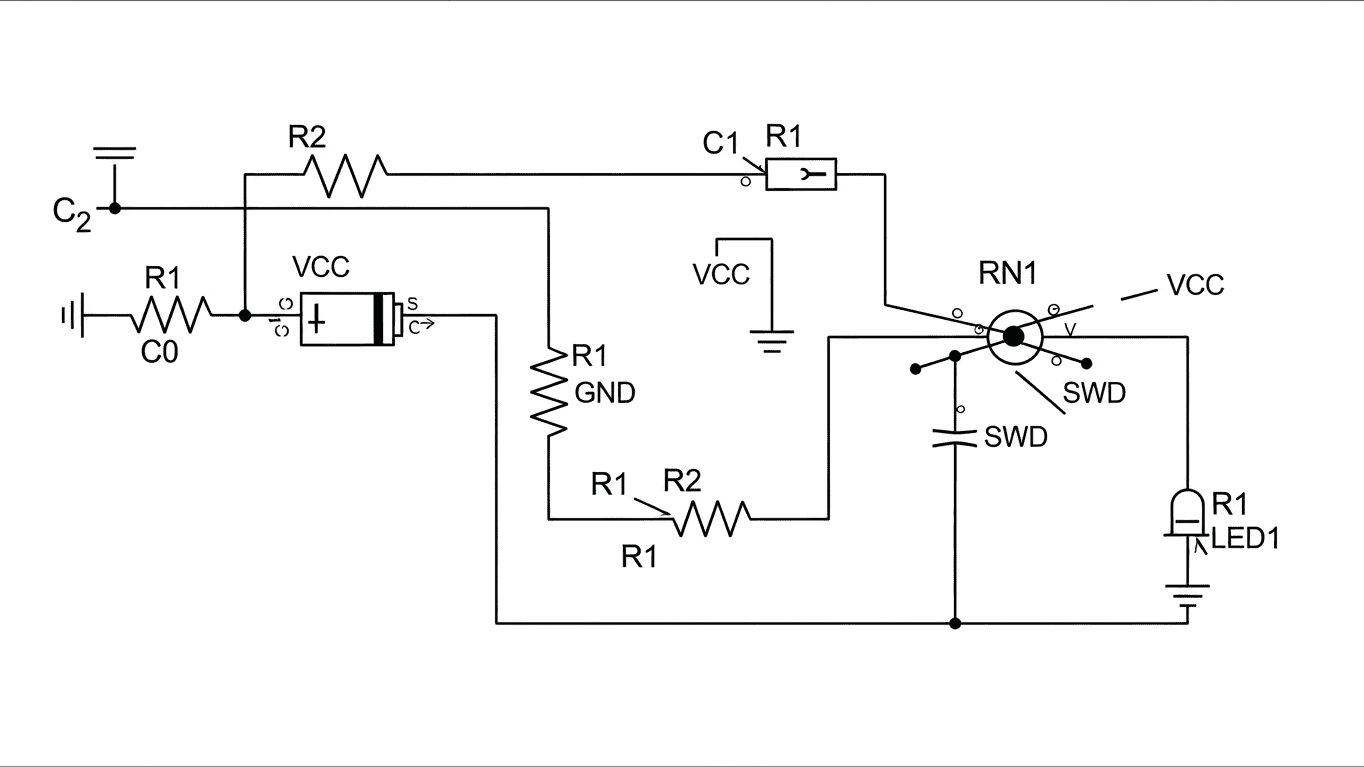

A 2 Float Switch Wiring Diagram illustrates the electrical connections for a system that uses two float switches to manage a device, most commonly a pump. Float switches are electromechanical devices that detect the level of a liquid. They typically consist of a buoyant ball or disc that rises and falls with the liquid level, activating or deactivating an electrical switch within the device. In a two-float switch setup, one float switch is usually set to turn a device ON at a low liquid level, and the other is set to turn it OFF at a high liquid level. This creates a reliable "on/off" cycle for your pump, preventing it from running dry or overflowing.

These diagrams are essential for several reasons. They provide a clear, visual representation of how the power flows from the source, through the switches, and to the controlled device. This helps prevent incorrect wiring, which can lead to damage to your equipment or even electrical hazards. A properly understood 2 Float Switch Wiring Diagram ensures:

- Correct pump operation (e.g., pumping out excess water when levels are high).

- Protection against dry running (e.g., stopping the pump when water levels are too low).

- Automation of fluid management tasks.

There are a few common configurations for a 2 Float Switch Wiring Diagram, often depending on whether you want to control a device to empty a tank or fill a tank. For example, in a sump pit application to prevent flooding, the configuration would typically be:

- High Level Float Switch: Set to trigger the pump ON when the water reaches a dangerous high level.

- Low Level Float Switch: Set to trigger the pump OFF once the water level has been sufficiently lowered.

Here's a simplified look at how the components might be connected in a typical system controlling a pump:

| Component | Function |

|---|---|

| Power Source | Provides electricity. |

| High Level Float Switch | Completes the circuit to turn the pump ON when water rises. |

| Low Level Float Switch | Breaks the circuit to turn the pump OFF when water lowers. |

| Pump | The device being controlled (e.g., to move water). |

The importance of a clear and accurate 2 Float Switch Wiring Diagram cannot be overstated for ensuring the safe and effective operation of any automated fluid control system.

For detailed and specific guidance on your particular setup, we highly recommend consulting the detailed diagrams and instructions provided in the resources section of this guide.