Navigating the electrical connections of a motor can seem daunting, but understanding the 2 Hp Single Phase Motor Wiring Diagram is a crucial step for anyone working with these common powerhouses. Whether you're a DIY enthusiast, a budding electrician, or simply trying to repair a piece of equipment, having a clear grasp of the wiring diagram ensures safety and proper functionality. This article will demystify the 2 Hp Single Phase Motor Wiring Diagram, guiding you through its essential components and applications.

What is a 2 Hp Single Phase Motor Wiring Diagram and How It's Used

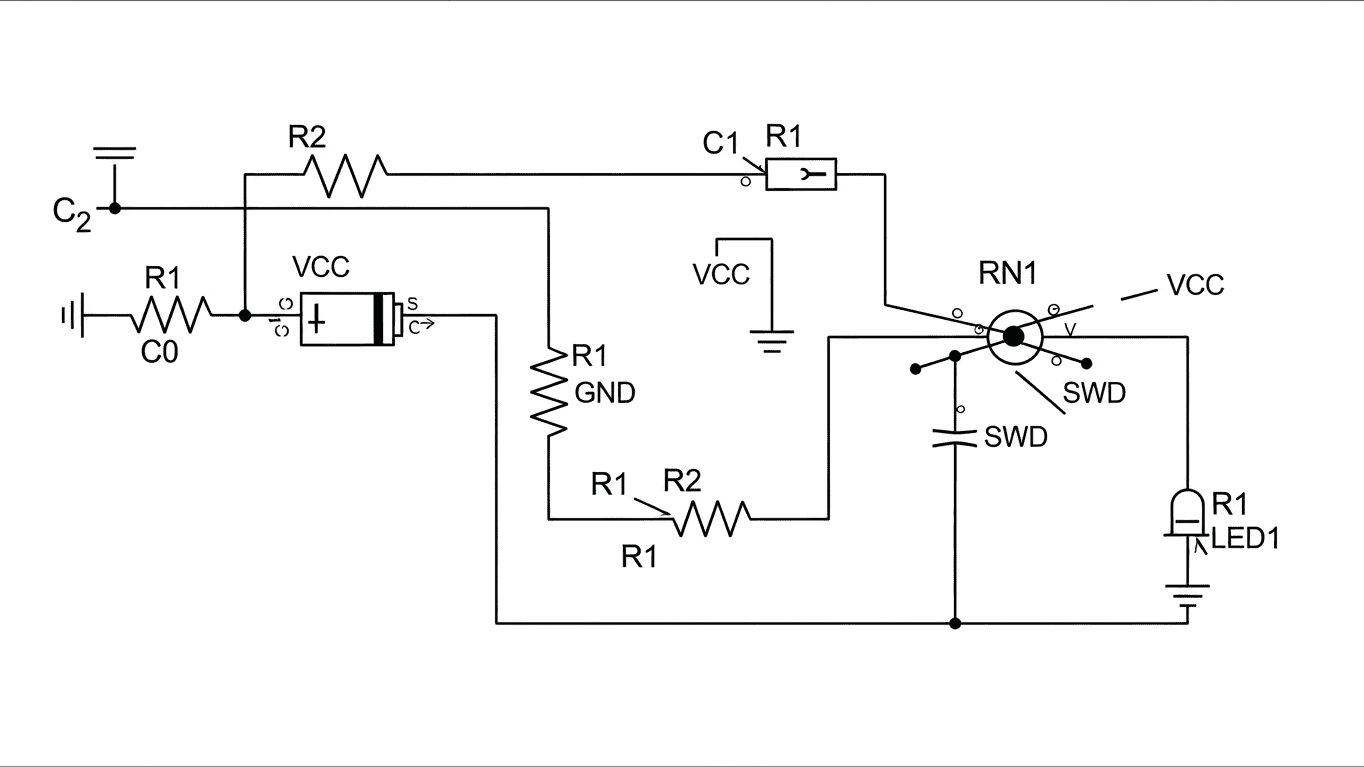

A 2 Hp Single Phase Motor Wiring Diagram is essentially a blueprint for how the electrical components of a 2 horsepower (Hp) single-phase motor are interconnected. Single-phase motors are widely used in homes and small businesses for a variety of applications, from powering pumps and fans to operating tools and appliances. The wiring diagram illustrates the path electricity takes to power the motor, including connections to the power supply, internal windings, and starting components. Properly interpreting and following this diagram is of utmost importance for safe and effective installation and maintenance.

These diagrams typically show the connections for the main winding, the start winding, and the capacitor (if applicable), which is vital for initiating the motor's rotation. They also indicate the terminals where the incoming power lines connect. For a typical 2 Hp single-phase motor, you'll often see connections for:

- Line (L)

- Neutral (N)

- Ground (G)

- Internal windings (often labeled M for Main and S for Start)

- Capacitor terminals

The specific layout can vary depending on the motor's design and manufacturer, but the core purpose remains the same: to provide a clear visual guide for electrical connections. Without this diagram, attempting to wire a motor would be a blind guess, potentially leading to damaged equipment, electrical hazards, or the motor failing to operate correctly. It is the universal language for motor installation professionals.

The use of a 2 Hp Single Phase Motor Wiring Diagram is multifaceted. For initial installation, it ensures that the motor is connected to the power source in the correct polarity and sequence. During troubleshooting, it helps identify faulty connections or components by allowing for systematic checking of each circuit. Maintenance personnel rely on it for disassembling and reassembling the motor correctly, especially when replacing parts like capacitors or switches. The diagram serves as a reference point, guaranteeing that all connections are made according to the manufacturer's specifications, which is critical for the longevity and performance of the motor.

To further illustrate, consider a common setup where a centrifugal switch is used to disconnect the start winding and capacitor once the motor reaches a certain speed. The wiring diagram will clearly show how this switch is integrated into the circuit. Some common wiring configurations can be summarized in a table:

| Component | Connection Point |

|---|---|

| Line Power | Terminal L1 |

| Neutral Power | Terminal N or L2 |

| Capacitor | Across Start and Main winding terminals |

| Centrifugal Switch | In series with the Start winding |

Understanding these basic elements and how they are represented on the diagram is the first step to confidently working with your 2 Hp Single Phase Motor Wiring Diagram. This knowledge empowers you to perform installations and repairs safely and efficiently.

For precise instructions tailored to your specific motor model, it is best to consult the official documentation provided by the manufacturer. Referencing the exact diagram for your unit will ensure accuracy and safety. The information provided here is a general guide to help you understand the fundamentals.