Understanding the 2 Phase Stepper Motor Wiring Diagram is crucial for anyone looking to effectively integrate these versatile motors into their projects. This diagram serves as a blueprint, guiding you through the connections needed to power and control the precise movements of a 2-phase stepper motor.

Decoding the 2 Phase Stepper Motor Wiring Diagram

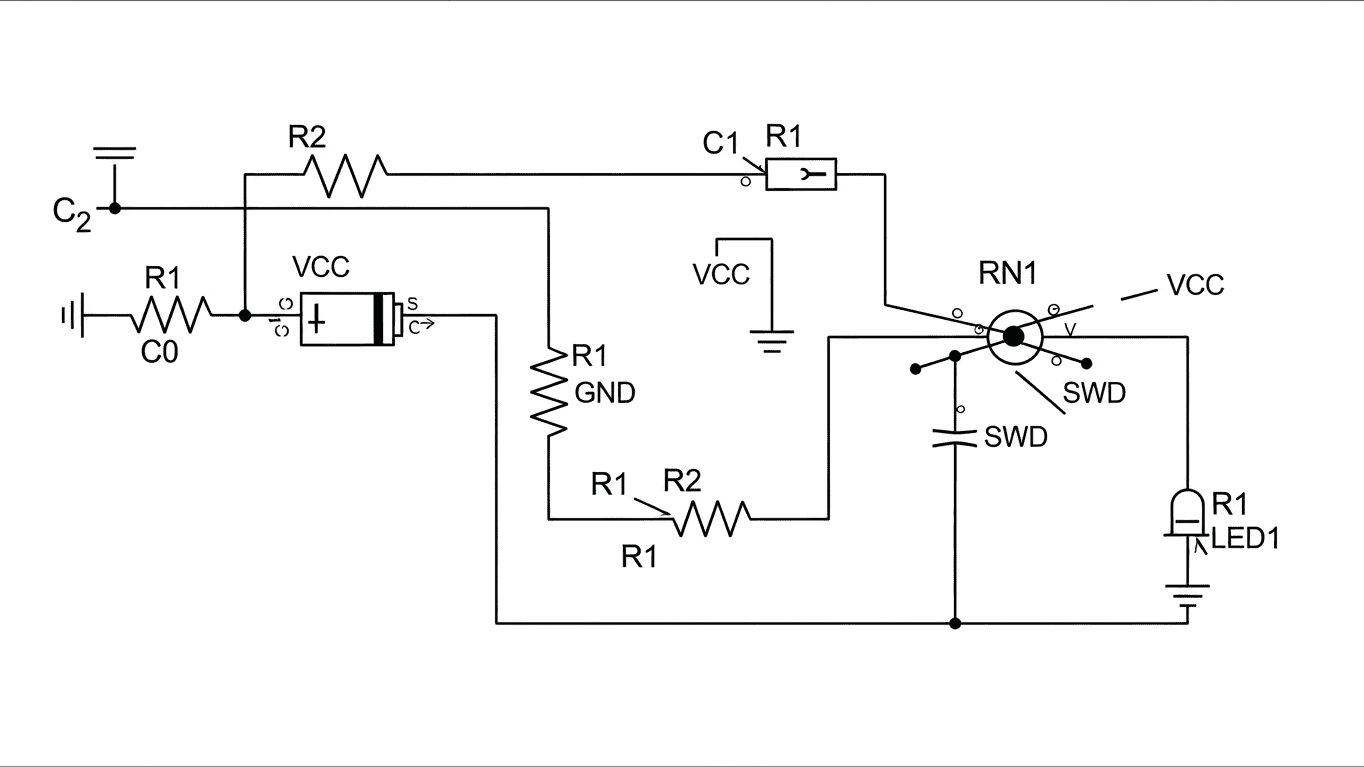

A 2 phase stepper motor is an electric motor that divides a full rotation into a number of equal steps. The motor has two independent coils, or "phases," that are energized in a specific sequence to achieve this stepped movement. The 2 Phase Stepper Motor Wiring Diagram illustrates how these coils, along with their associated wires, should be connected to a motor driver. This driver is the intermediary that interprets control signals and delivers the correct current pulses to each phase. Without a clear understanding of the wiring diagram, connecting the motor incorrectly can lead to no movement, erratic behavior, or even permanent damage to the motor or driver. The importance of a correct wiring diagram cannot be overstated for successful stepper motor operation.

Stepper motors, by their nature, offer excellent positional accuracy and repeatability, making them ideal for applications where precise movement is required. Common uses include:

- 3D printers and CNC machines for accurate axis control.

- Robotics for precise joint articulation.

- Automated manufacturing equipment for pick-and-place operations.

- Camera pan-tilt mechanisms for smooth and controlled aiming.

- Medical equipment requiring delicate and consistent motion.

The 2 Phase Stepper Motor Wiring Diagram helps distinguish between different types of 2-phase stepper motors, primarily unipolar and bipolar. The wiring configuration differs significantly between these two:

- Unipolar Stepper Motors: These have five or six wires. They are simpler to drive as one winding of each phase is connected to a common center tap, which is connected to the positive supply. The other ends of the windings are switched to ground.

- Bipolar Stepper Motors: These typically have four wires. They are more efficient and offer higher torque but require more complex driver circuitry because the current direction in each winding must be reversed.

Here's a simplified overview of common wiring scenarios for bipolar motors:

| Phase | Coil A Wires | Coil B Wires |

|---|---|---|

| Phase A | A1, A2 | |

| Phase B | B1, B2 |

The diagram will clearly label these wires, allowing you to connect them to the corresponding outputs on your stepper motor driver. Always double-check the labels on both the motor and the driver against the 2 Phase Stepper Motor Wiring Diagram.

To ensure you have the most accurate and project-specific connection information, please refer to the detailed 2 Phase Stepper Motor Wiring Diagram provided in the next section.