Navigating the complexities of electrical systems can sometimes feel daunting, especially when dealing with specialized components. For those working with machinery that requires variable speed capabilities, understanding the 2 Speed 2 Winding Motor Wiring Diagram is crucial. This diagram serves as a vital blueprint, guiding technicians and DIY enthusiasts through the process of correctly connecting a motor that offers two distinct operating speeds, achieved through its unique two-winding configuration.

What is a 2 Speed 2 Winding Motor Wiring Diagram and How is it Used?

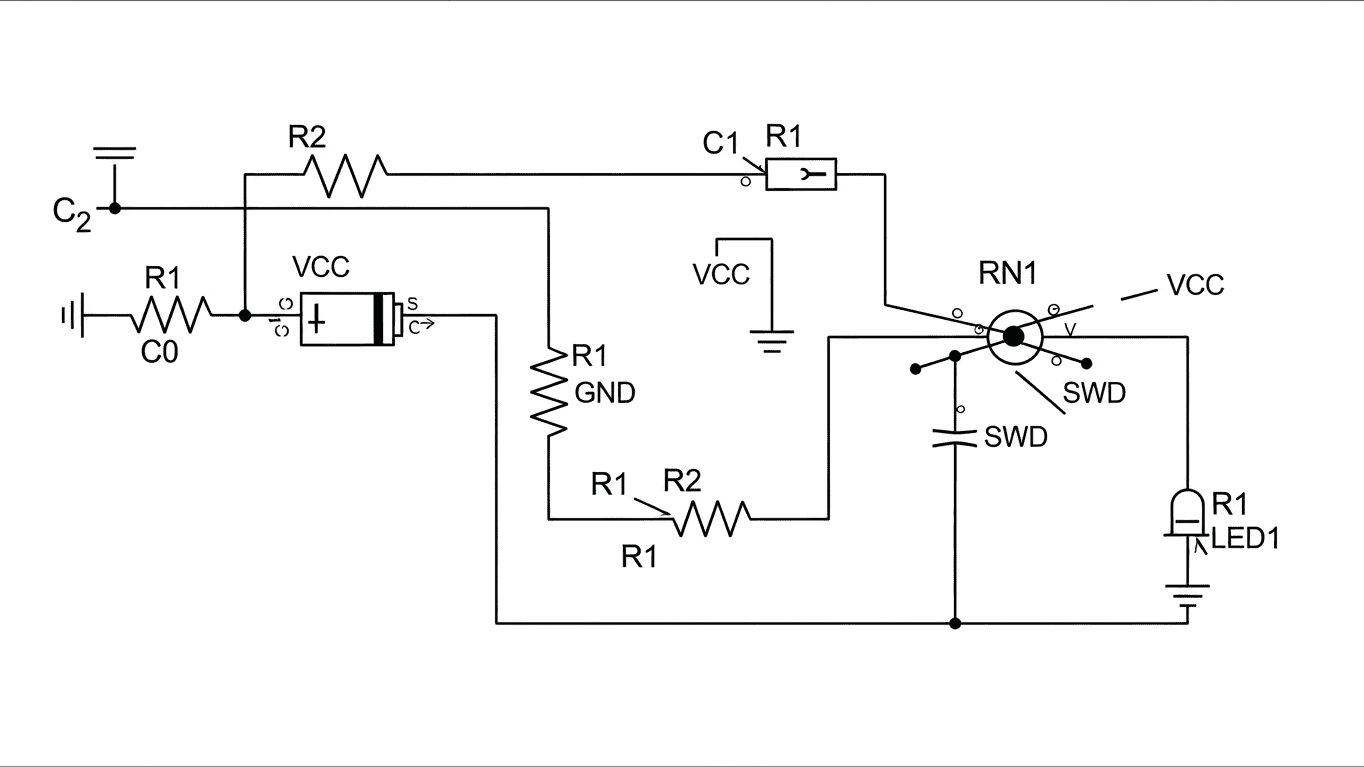

A 2 Speed 2 Winding Motor Wiring Diagram is a schematic representation that illustrates how to connect a specific type of electric motor designed to operate at two different speeds. These motors are not simply variable speed through electronics; they achieve their speed changes by having two separate sets of windings within the motor. Each winding is designed to produce a different rotational speed when energized. The wiring diagram shows the terminals of the motor and how they should be connected to a power source and a control mechanism (like a switch or relay) to select between these two windings. The importance of a correct 2 Speed 2 Winding Motor Wiring Diagram cannot be overstated, as improper wiring can lead to motor damage, electrical hazards, or the motor simply not functioning as intended.

The application of these motors is widespread, particularly in equipment where different operational demands require varying levels of performance. For instance, you might find them in:

- Industrial fans that need a high speed for maximum airflow and a low speed for quieter operation or reduced energy consumption.

- Pumps designed for different flow rates or pressure requirements.

- Machine tools where precision at low speeds and rapid material removal at high speeds are both necessary.

- Some types of conveyors that handle different product weights or processing stages.

The control method for a 2 Speed 2 Winding Motor typically involves switching power to one winding or the other. This is usually accomplished with a multi-position switch. The diagram will detail which motor terminals correspond to each winding and how to interrupt or direct power to them.

Here's a simplified overview of how the connection points might be represented:

| Winding | Typical Terminal Group | Function |

|---|---|---|

| Speed 1 (e.g., Low Speed) | T1-T4, T5-T8 | Connects power to the winding designed for slower rotation. |

| Speed 2 (e.g., High Speed) | T1-T7, T4-T8 | Connects power to the winding designed for faster rotation. |

| Common | T1 | Shared connection point for both windings. |

When you consult a specific 2 Speed 2 Winding Motor Wiring Diagram, pay close attention to the terminal numbering, as this is standardized but can vary slightly between manufacturers. The diagram will clearly show which terminals are connected to the start and end of each winding, and how to select one over the other using your control switch.

If you have a specific 2 Speed 2 Winding Motor that you need to wire, refer to the detailed diagrams and documentation provided by the motor manufacturer. These resources are indispensable for ensuring a safe and functional installation.