Understanding a 2 Speed Pump Wiring Diagram is key to properly connecting and operating your two-speed pump. Whether it's for your swimming pool, spa, or other water circulation needs, a clear diagram ensures safety and efficiency. This article will break down what a 2 Speed Pump Wiring Diagram entails, making it accessible for anyone to grasp.

What is a 2 Speed Pump Wiring Diagram and How is it Used?

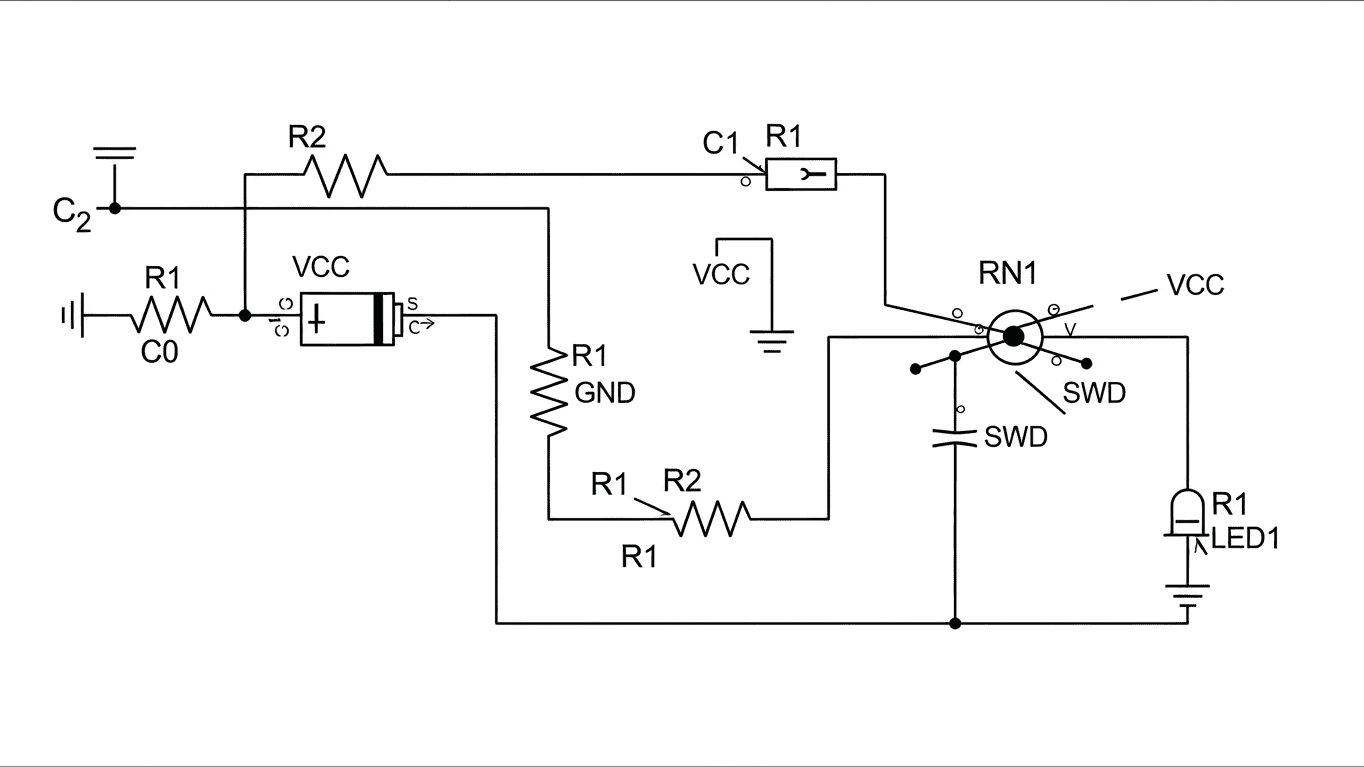

A 2 Speed Pump Wiring Diagram is a visual representation that shows how the electrical components of a two-speed pump are connected. These pumps have two distinct operating speeds, typically referred to as "low speed" and "high speed." The wiring diagram illustrates the pathways for electricity to flow to the motor windings that control these different speeds. This allows for flexible operation, saving energy when lower speeds are sufficient and providing more power when needed. Having a correct 2 Speed Pump Wiring Diagram is essential for safe installation and troubleshooting.

These diagrams are crucial for electricians, pool technicians, and even DIY homeowners. They act as a blueprint, guiding the connection of power sources, switches, relays, and the pump motor itself. Here are some common uses:

- Installation of a new two-speed pump.

- Replacing an old or damaged pump motor.

- Troubleshooting electrical issues with the pump.

- Upgrading pump controls.

A typical 2 Speed Pump Wiring Diagram might show the following:

| Component | Purpose |

|---|---|

| Power Input (L1, L2, Ground) | Supplies electricity to the pump. |

| Motor Windings (Low Speed) | Electromagnetic coils that create low-speed rotation. |

| Motor Windings (High Speed) | Electromagnetic coils that create high-speed rotation. |

| Selector Switch/Controller | Allows the user to choose between low and high speeds. |

| Capacitor | Aids in starting the motor. |

The diagram will clearly indicate which wires connect to which terminals on the motor and control components. For instance, it will show how the selector switch directs power to either the low-speed or high-speed windings. Some diagrams might also include safety features like overload protection or specific wiring requirements for different voltage systems. Following these instructions precisely prevents electrical hazards and ensures the pump operates as intended. Understanding the sequence of connections is paramount, as miswiring can lead to motor damage or, worse, electrical shock. The ability to switch between speeds offers significant benefits, such as:

- Reduced energy consumption during continuous filtration.

- Quieter operation at lower speeds.

- Increased water flow and pressure when high speed is required.

Now that you have a better understanding of what a 2 Speed Pump Wiring Diagram is, you can confidently refer to the specific diagram provided by your pump manufacturer. This detailed guide will be your best resource for accurate and safe connections.