Understanding the intricacies of a 2 Wire AC Proximity Sensor Wiring Diagram is crucial for anyone working with industrial automation, machinery, or any application requiring contactless detection. This diagram serves as a blueprint, guiding the correct installation and operation of these versatile sensors, ensuring reliable performance in various environments. A proper grasp of the 2 Wire Ac Proximity Sensor Wiring Diagram simplifies troubleshooting and maximizes the lifespan of your equipment.

What is a 2 Wire AC Proximity Sensor Wiring Diagram and How Are They Used?

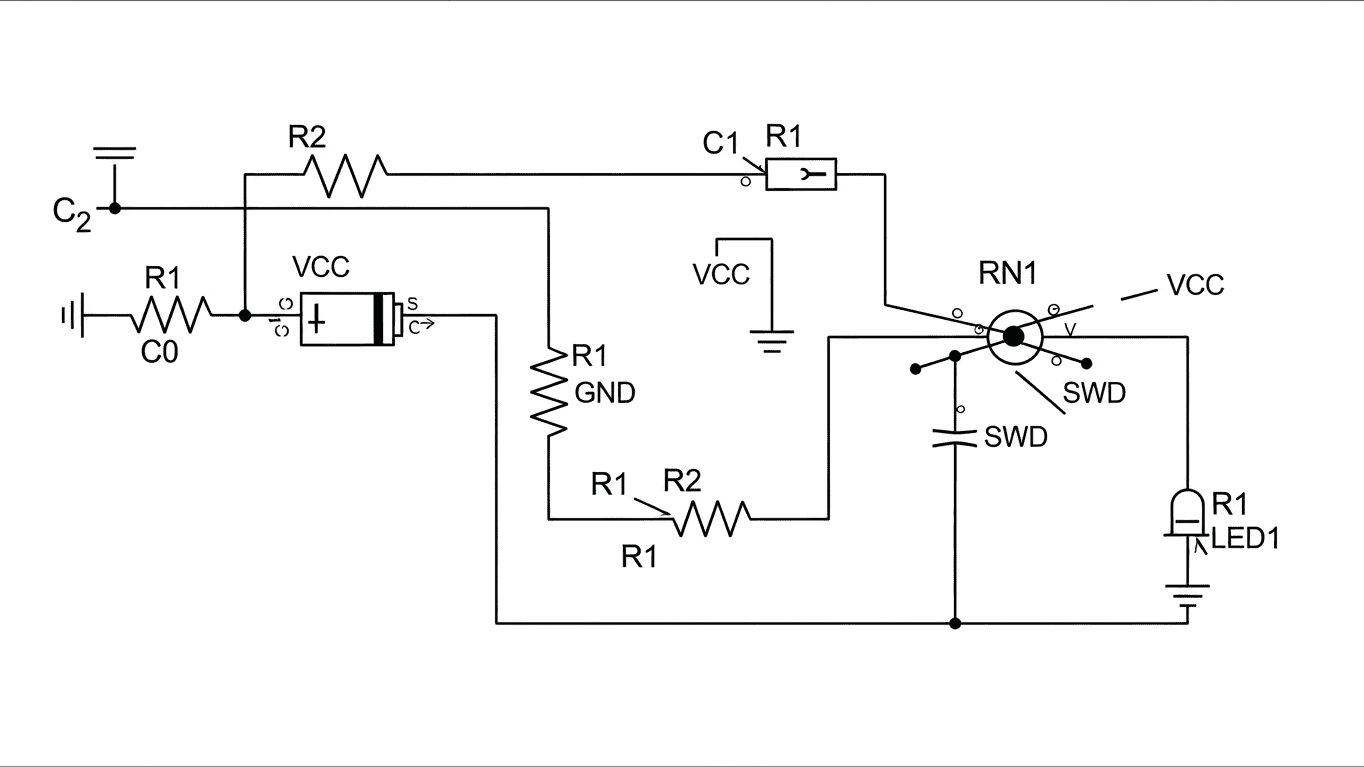

A 2 Wire AC Proximity Sensor Wiring Diagram illustrates how to connect a specific type of sensor that detects the presence of metallic objects without physical contact. Unlike 3-wire or 4-wire sensors, these AC versions utilize the power supply lines themselves to transmit the signal. This simplifies wiring, making them a popular choice in applications where space or the number of available wiring conductors is limited. They are commonly found in conveyor belt systems, packaging machinery, and machine tool positioning.

- Simplicity: Reduced wiring complexity compared to other sensor types.

- Cost-effectiveness: Often less expensive due to fewer components and simpler circuitry.

- Durability: Their non-contact nature minimizes wear and tear.

The core function of a 2-wire AC proximity sensor is to act as an electronic switch. When a target object enters the sensor's detection field, it changes the sensor's internal state, which in turn affects the current flow through the two wires. This change in current is what the connected control system interprets as a signal. The specific behavior – whether the sensor is normally open (NO) or normally closed (NC) – determines how the current changes:

- Normally Open (NO): The sensor draws minimal current when no target is present. When a target is detected, the sensor conducts more current, signaling the presence of the object.

- Normally Closed (NC): The sensor draws a small, constant current even when no target is present. When a target is detected, the sensor's impedance increases, reducing the current flow and signaling the absence of the object (or vice versa depending on the specific NC definition).

The diagram will typically show how these two wires connect to the power source (often a mains AC voltage) and to the input of a control device, such as a relay, PLC (Programmable Logic Controller), or counter. The control device then monitors the current drawn by the sensor to determine the presence or absence of the target object. Understanding the distinction between NO and NC is vital for correct integration into your control logic. The following table summarizes key characteristics:

| Feature | 2 Wire AC Proximity Sensor |

|---|---|

| Number of Wires | 2 |

| Power Supply | AC mains voltage |

| Signal Transmission | Via power supply lines |

| Typical Applications | Conveyors, packaging, machine tools |

The correct implementation of a 2 Wire AC Proximity Sensor Wiring Diagram is paramount for ensuring accurate detection and reliable operation of automated systems. Miswiring can lead to sensor damage, incorrect signals, and system malfunctions. Always refer to the manufacturer's specific datasheet and wiring diagram for your particular sensor model to guarantee a safe and effective installation.

For a comprehensive understanding and to avoid potential pitfalls, always consult the specific 2 Wire Ac Proximity Sensor Wiring Diagram provided by the sensor manufacturer. This ensures that you are working with the exact specifications for your chosen component.