Understanding a 2 Wire Crank Sensor Wiring Diagram is essential for anyone dealing with automotive diagnostics and repair. This diagram provides a visual guide to how the crankshaft position sensor, a crucial component in modern engines, connects to the vehicle's computer. Whether you're a DIY enthusiast or a seasoned mechanic, a clear grasp of the 2 Wire Crank Sensor Wiring Diagram can save you time and frustration when troubleshooting engine performance issues.

The Basics of a 2 Wire Crank Sensor Wiring Diagram

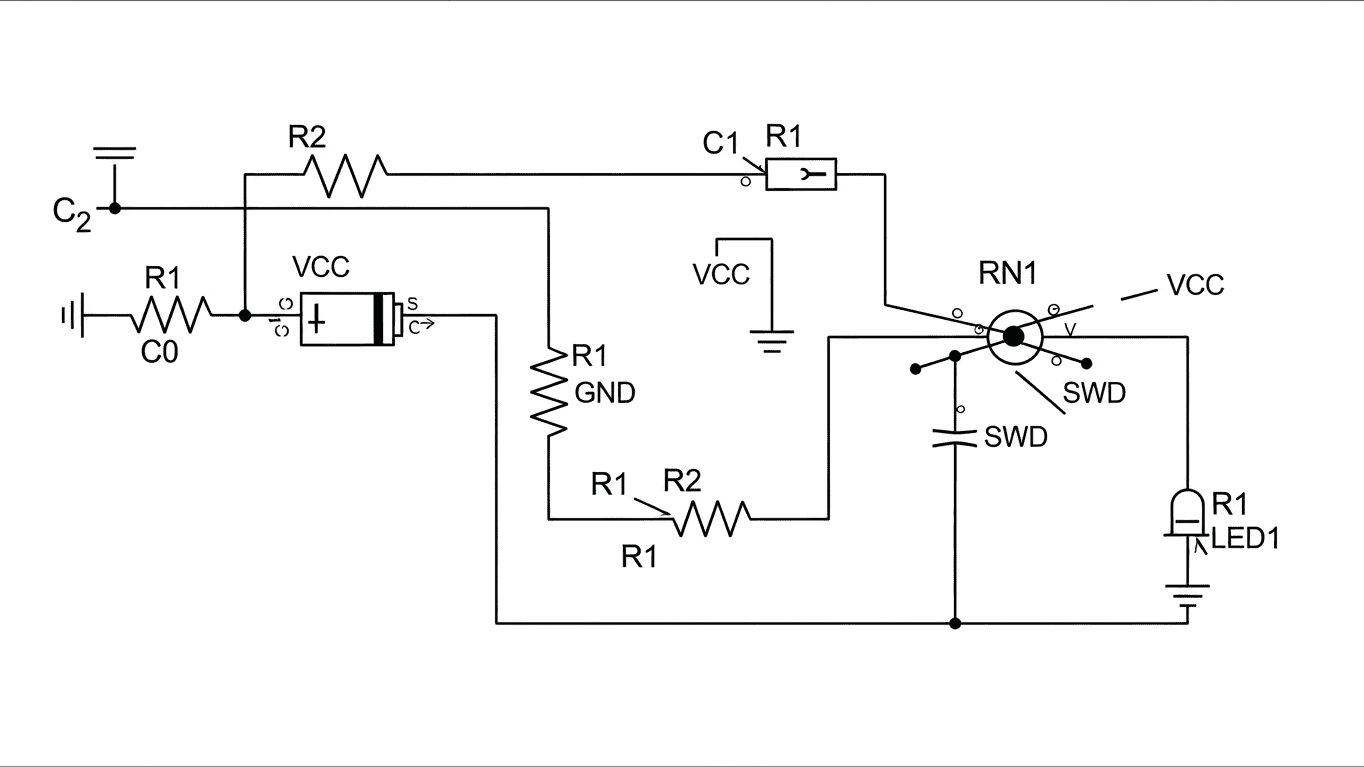

A crankshaft position sensor, often referred to as a CKP sensor, plays a vital role in an internal combustion engine. It detects the rotational speed and position of the crankshaft, sending this information to the engine control module (ECM) or powertrain control module (PCM). This data is critical for the ECM to accurately time fuel injection and ignition spark. Without this information, the engine simply wouldn't run. A 2 Wire Crank Sensor Wiring Diagram specifically illustrates the connections for a simpler type of CKP sensor, typically an inductive or variable reluctance sensor. These sensors usually have two wires: one for power (or signal ground) and one for the signal output.

The simplicity of the 2-wire system is a key characteristic. Unlike more complex Hall effect sensors that might require a separate power supply and ground, a typical 2-wire inductive sensor generates its own signal as a magnetic field changes due to the passing reluctor wheel (a toothed wheel attached to the crankshaft). The wiring diagram shows how these two wires connect to the vehicle's wiring harness, ultimately leading to the ECM. For example, one wire might be connected to the ECM's signal input pin, and the other to the ECM's ground or a reference ground. The correct wiring is paramount for the sensor to function and transmit accurate data to the engine's brain.

When examining a 2 Wire Crank Sensor Wiring Diagram, you'll typically find the following elements:

- The sensor itself, depicted with its two connection points.

- The wiring harness, showing the color codes and gauge of the wires.

- Connection points within the vehicle's wiring harness.

- The destination of each wire, usually the ECM or PCM, with specific pin numbers indicated.

It's important to note that wire colors can vary between manufacturers and even vehicle models. Always refer to a specific diagram for your vehicle's make, model, and year to ensure accuracy. Misinterpreting the diagram can lead to incorrect connections and potential damage to the sensor or the ECM.

When working with a 2 Wire Crank Sensor Wiring Diagram, it is highly recommended to use the specific diagram provided by your vehicle's manufacturer or a reputable automotive repair manual. These resources offer the most accurate and detailed information for your particular application.