Understanding the 2 Wire Pressure Transducer Wiring Diagram is crucial for anyone working with pressure sensing applications. This simple yet effective method of connecting pressure transducers streamlines installation and troubleshooting, making it a popular choice in various industries. We'll break down what it is and how it works.

Understanding the 2 Wire Pressure Transducer Wiring Diagram

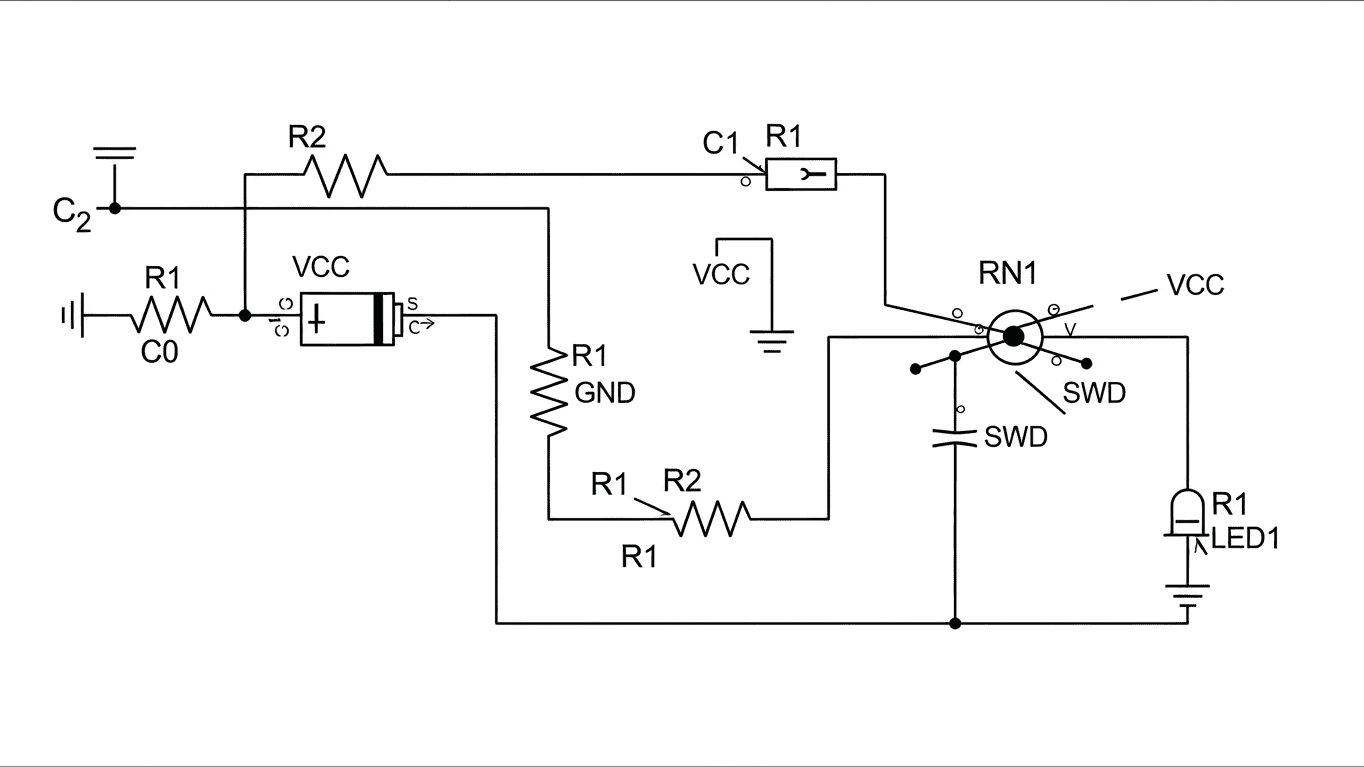

A 2 Wire Pressure Transducer Wiring Diagram represents the most straightforward method for connecting a pressure transducer to a power source and a monitoring device. Unlike more complex setups, this system utilizes just two wires to transmit both power to the transducer and the pressure signal back. This design significantly reduces wiring complexity, saving time and reducing the potential for errors during installation. Essentially, the transducer acts as a variable resistor or current source that changes its output based on the applied pressure, and this change is detected by the connected equipment.

The simplicity of the 2 Wire Pressure Transducer Wiring Diagram makes them ideal for a wide range of applications. They are commonly found in:

- HVAC systems for monitoring air and water pressure.

- Industrial process control for managing fluid and gas pressures.

- Automotive applications for engine and fuel pressure sensing.

- Water and wastewater treatment plants.

When implementing a 2 Wire Pressure Transducer Wiring Diagram, there are a few key considerations. The transducer itself often requires a specific voltage range to operate correctly. The connected device, such as a PLC (Programmable Logic Controller) or a dedicated display, must be capable of sourcing this voltage and interpreting the varying current or resistance signal. Here’s a simplified illustration of the flow:

| Wire 1 | Wire 2 |

|---|---|

| Power Source (+) → Transducer → Pressure Signal Output | ← Pressure Signal Output ← Transducer ← Power Source (-) |

For detailed guidance and specific examples, please refer to the comprehensive resources available in the next section.