When working on your vehicle's engine, understanding the various sensors and their connections is crucial for proper maintenance and troubleshooting. One such component, the coolant temperature sensor, plays a vital role in your engine's performance. For those delving into its intricacies, the 2 Wire Temp Sensor Coolant Temperature Sensor Wiring Diagram is an essential reference. This article will demystify this diagram and explain its significance.

What is a 2 Wire Temp Sensor Coolant Temperature Sensor Wiring Diagram and How is it Used?

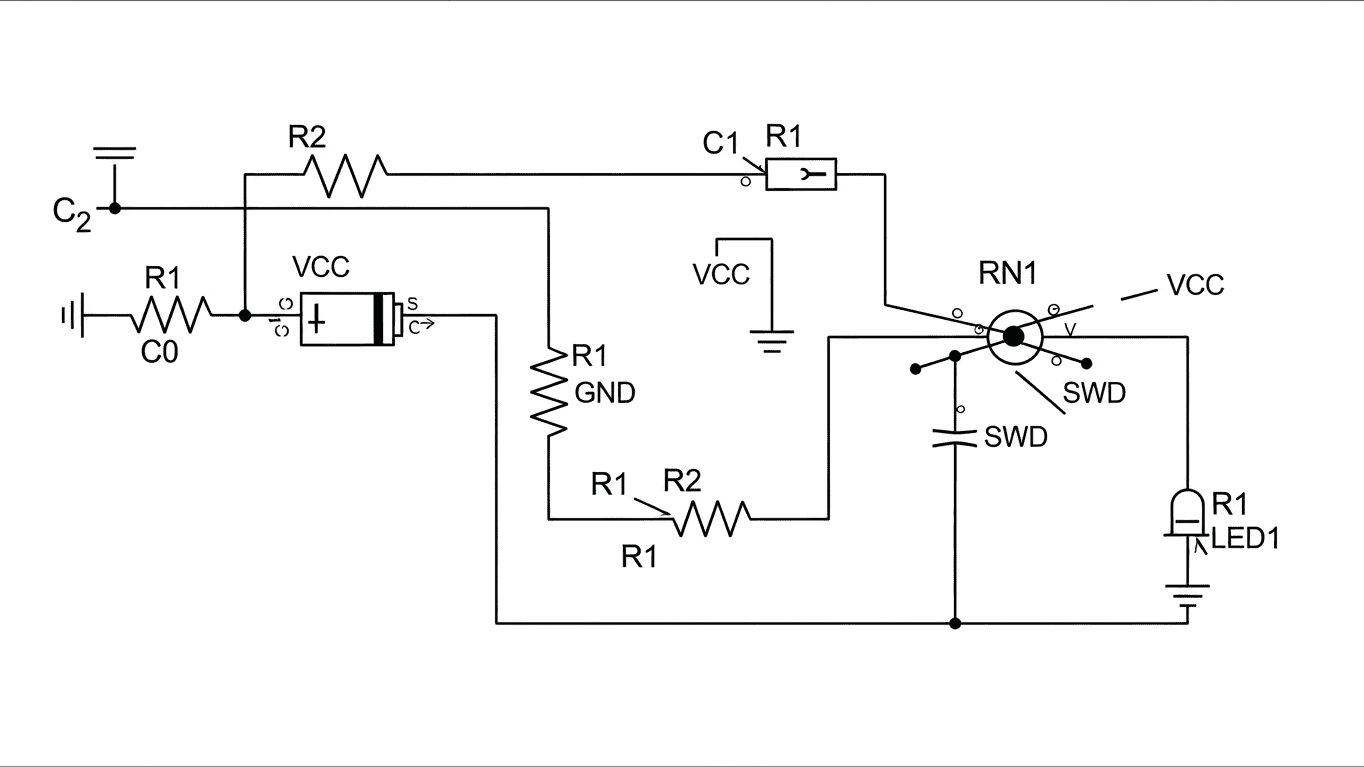

A 2 Wire Temp Sensor Coolant Temperature Sensor Wiring Diagram is a schematic that illustrates how a specific type of engine coolant temperature sensor connects to the vehicle's electrical system. Unlike some other sensors that might have more complex wiring, these two-wire sensors are generally simpler. They typically consist of a thermistor, a component whose electrical resistance changes with temperature. One wire usually provides a reference voltage from the engine control module (ECM) or powertrain control module (PCM), while the other wire carries the varying resistance signal back to the ECM/PCM.

The primary function of the coolant temperature sensor is to inform the ECM/PCM about the engine's operating temperature. This information is critical for several engine management functions. For instance, the ECM/PCM uses this data to:

- Adjust the air-fuel mixture for optimal combustion.

- Control idle speed.

- Determine fuel injector pulse width.

- Engage cooling fans when the engine reaches a certain temperature.

- Trigger diagnostic trouble codes (DTCs) if the sensor malfunctions.

The importance of a correctly functioning coolant temperature sensor cannot be overstated. A faulty sensor can lead to poor fuel economy, rough idling, engine stalling, and even potential engine damage if the engine overheats without the cooling fans engaging. When diagnosing a coolant temperature sensor issue, the wiring diagram is indispensable. It allows for systematic testing of the sensor itself, as well as the wiring harness and the ECM/PCM connections. A typical diagnostic procedure might involve:

- Verifying battery voltage at the sensor connector.

- Measuring the sensor's resistance at different temperatures.

- Checking for continuity in the wiring.

- Confirming proper ground connections.

To gain a deeper understanding of the specific connections for your vehicle, refer to the 2 Wire Temp Sensor Coolant Temperature Sensor Wiring Diagram provided in your vehicle's service manual.