Delving into the world of industrial machinery often involves understanding intricate electrical systems. A critical component in many applications is the 2 Speed Motor Wiring Diagram 3 Phase. This diagram is essential for correctly connecting motors that can operate at two distinct speeds, a feature crucial for optimizing performance and energy efficiency in a wide range of equipment.

The Fundamentals of a 2 Speed Motor Wiring Diagram 3 Phase

A 2 Speed Motor Wiring Diagram 3 Phase outlines the connections needed to achieve two different operational speeds from a single three-phase induction motor. These motors are designed with multiple windings, or coils, within their stator. By cleverly switching the power supply between these different winding configurations, the motor's speed can be altered. This allows for greater flexibility in applications where a single, fixed speed is not ideal. For instance, a fan might require a lower speed for quiet operation and energy saving during off-peak times, and a higher speed for maximum airflow when needed.

The method for achieving these two speeds typically involves one of two primary configurations: the Dahlander connection or separate windings. The Dahlander connection is a more compact and efficient method that utilizes a single stator with specially arranged windings. This method involves connecting the motor's terminals in specific ways to alter the number of effective poles, thereby changing the speed. Alternatively, some motors have entirely separate sets of windings, each designed for a specific speed, and the wiring diagram then shows how to energize one set or the other.

- Understanding the wiring diagram is paramount for safe and correct installation.

- This diagram dictates the flow of electricity to the motor's internal windings.

-

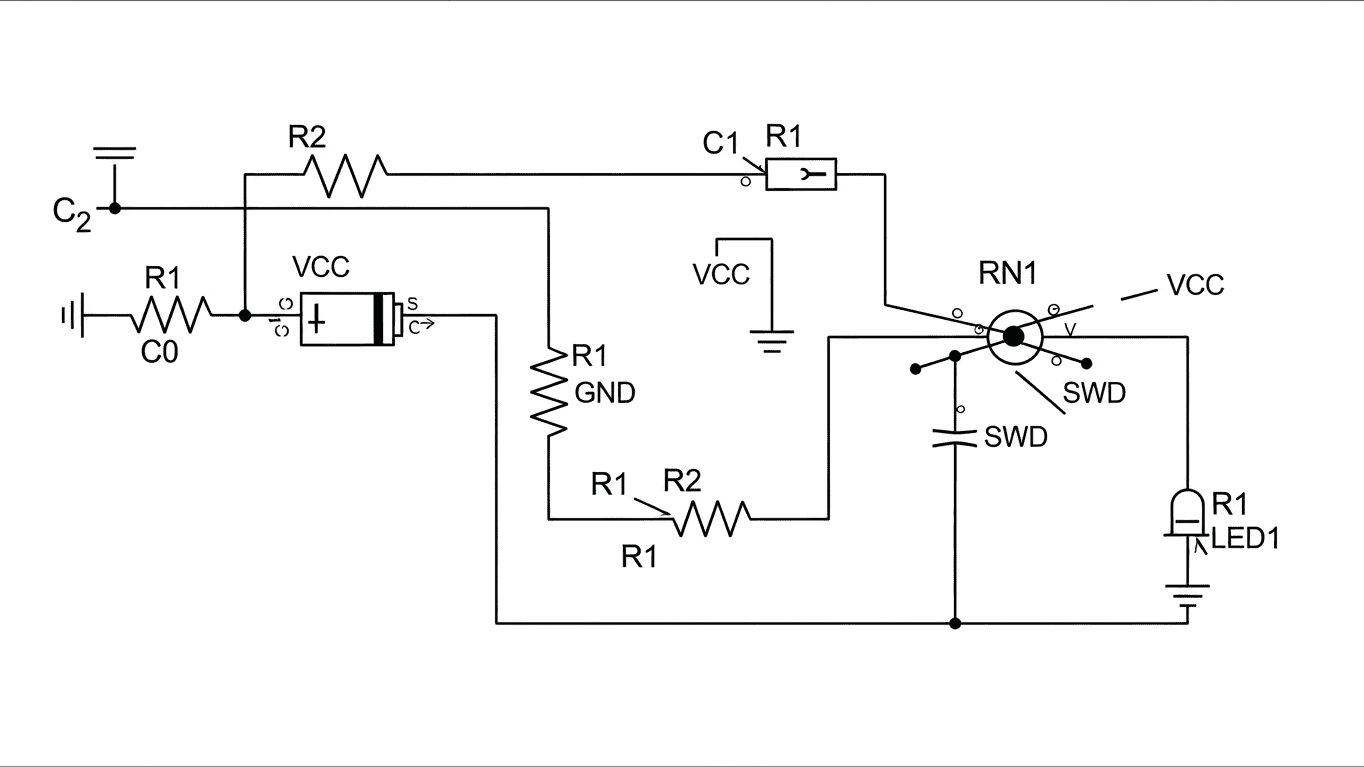

Key components represented in the diagram often include:

- Motor terminals (e.g., L1, L2, L3, T1, T2, T3, etc.)

- Contactors or switches for speed selection

- Overload protection devices

- Power source connections

A typical 2 Speed Motor Wiring Diagram 3 Phase will illustrate how to wire for low speed and high speed. For example, in a Dahlander setup, low speed is usually achieved by connecting the windings in a "series parallel" configuration, effectively doubling the number of poles. High speed is then achieved by connecting the windings in a "series" configuration, resulting in fewer poles. The diagram precisely shows which terminals are connected together and to the power supply for each speed setting. Failure to adhere to the diagram can lead to motor damage, incorrect operation, or electrical hazards.

Here's a simplified representation of what you might find:

| Speed | Typical Connection Type | Effect on Poles |

|---|---|---|

| Low | Dahlander (Series Parallel) | Doubled Poles (e.g., 4-pole to 8-pole) |

| High | Dahlander (Series) | Fewer Poles (e.g., 4-pole) |

Consulting the specific 2 Speed Motor Wiring Diagram 3 Phase provided by the motor manufacturer is always the most reliable approach for any installation or troubleshooting. This document contains the exact specifications and connection sequences tailored to that particular motor model.

To ensure you have the most accurate and detailed information for your specific application, please refer to the detailed schematics and documentation provided in the next section.