Understanding the 2 Wire 4 20ma Wiring Diagram is fundamental for anyone working with industrial instrumentation and process control. This common wiring configuration is a robust and reliable method for transmitting sensor signals and controlling actuators across various applications. Let's delve into what makes this diagram so prevalent and how it functions.

What is a 2 Wire 4 20mA Loop?

The 2 Wire 4 20mA loop is a standard signaling method used in industrial environments to transmit information from sensors to control systems. In this setup, two wires are used to both power the sensor and carry the output signal. The "4 20mA" refers to the current range used for the signal. At the lowest measured value, the sensor outputs 4 milliamps (mA) of current. As the measured value increases, the current output rises proportionally, reaching 20mA at the highest measured value. This current loop design is highly effective because it is less susceptible to electrical noise and voltage drops over long distances compared to voltage-based signaling.

This type of wiring offers several distinct advantages that contribute to its widespread adoption. For instance, the use of current instead of voltage makes the system more resilient to interference. Additionally, the 4mA minimum signal provides a built-in check for the integrity of the loop. If the current drops to 0mA, it indicates a fault, such as a broken wire or a disconnected sensor, which is a critical advantage for system monitoring. The components involved in a typical 2 wire 4 20mA system include:

- The Sensor: This device measures a physical parameter like temperature, pressure, or flow.

- The Power Supply: A DC power source that provides the necessary voltage to operate the sensor and the loop.

- The Receiver: This is usually a controller or a display that interprets the 4-20mA signal.

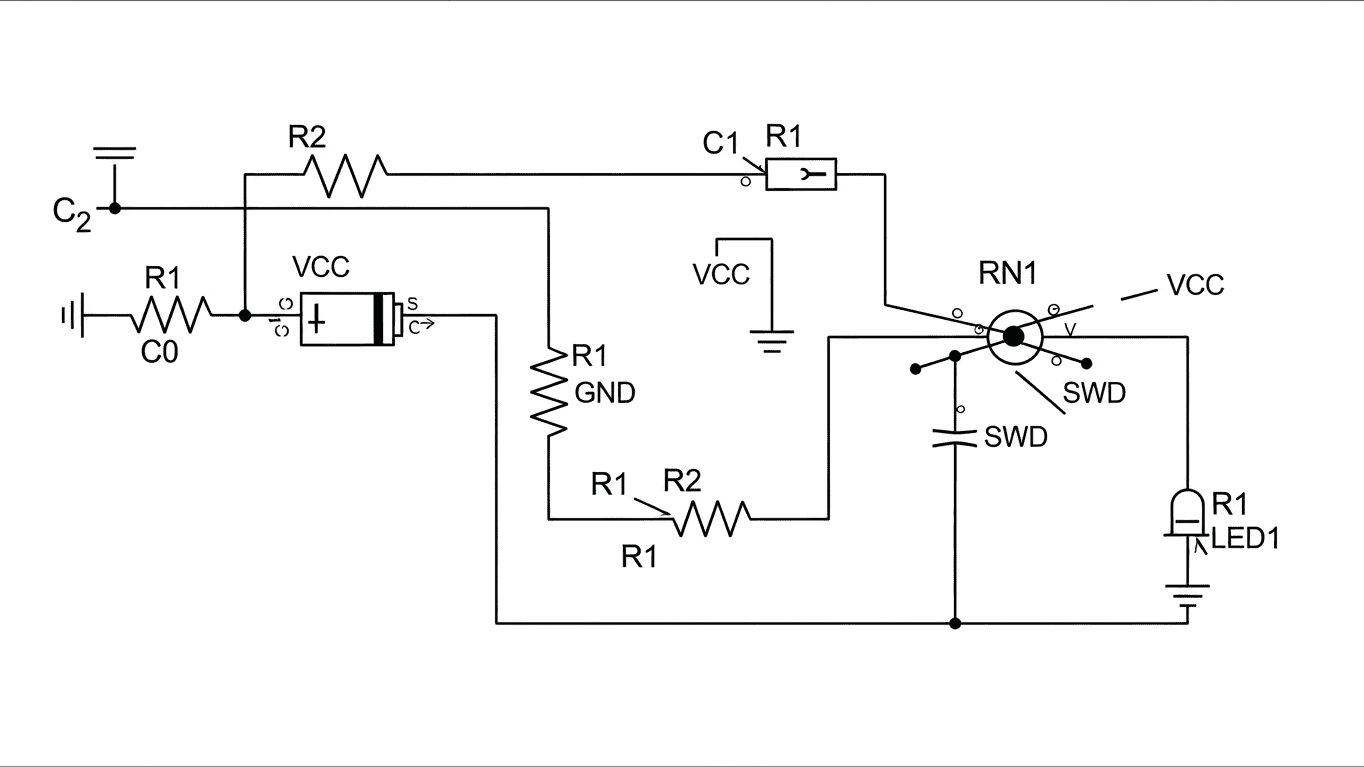

The beauty of the 2 Wire 4 20mA Wiring Diagram lies in its simplicity and inherent reliability. It allows for efficient data transmission and fault detection using minimal wiring. Here's a basic illustration of how it works with different measurements:

| Measured Value | Current Output (mA) |

|---|---|

| Minimum (e.g., 0°C) | 4mA |

| Mid-Range (e.g., 50°C) | 12mA |

| Maximum (e.g., 100°C) | 20mA |

This consistent relationship between the measured value and the current output makes it straightforward for control systems to accurately interpret the sensor's readings. The true power of this system lies in its ability to provide a continuous, reliable, and error-detecting signal for critical industrial processes .

To fully grasp how to implement and troubleshoot these essential circuits, it is highly recommended to consult the detailed explanations and diagrams provided in the comprehensive guide available within this article.