Understanding the intricacies of your vehicle's engine management system is crucial for proper maintenance and troubleshooting. One vital component is the camshaft position sensor, and for many, a clear understanding of the 2 Wire Cam Sensor Wiring Diagram is the first step. This diagram serves as a roadmap, guiding technicians and DIY enthusiasts through the electrical connections that allow this sensor to communicate with the engine control unit (ECU).

What is a 2 Wire Cam Sensor and How it Works

A 2-wire camshaft position sensor, often referred to as a CMP sensor, plays a critical role in modern internal combustion engines. Its primary function is to detect the position of the camshaft, specifically identifying when a cylinder is nearing the top of its compression stroke. This information is then transmitted to the engine control unit (ECU), which uses it for a variety of essential functions. Without accurate data from the CMP sensor, the ECU would struggle to precisely control ignition timing, fuel injection, and valve timing, leading to poor engine performance, reduced fuel efficiency, and potentially engine damage.

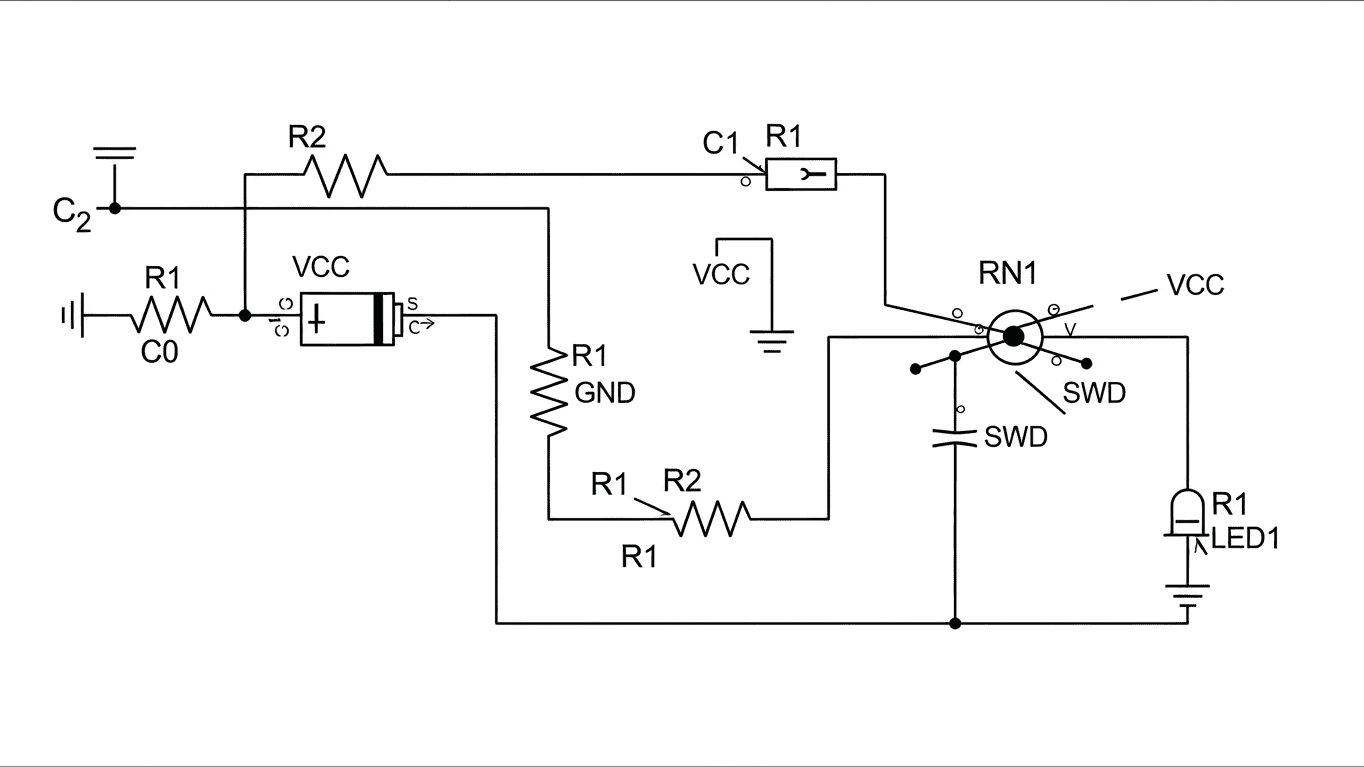

The simplicity of the 2-wire design often belies its importance. Typically, one wire carries a signal ground, and the other carries the sensor's output signal. The sensor itself usually operates on one of two common principles: Hall effect or variable reluctance. A Hall effect sensor uses a magnet and a semiconductor chip. As the camshaft rotates, a target on the camshaft passes by the sensor, altering the magnetic field and generating a voltage signal. A variable reluctance sensor, on the other hand, generates a signal by a coil of wire that experiences a changing magnetic flux as a toothed wheel on the camshaft rotates past it. Regardless of the internal mechanism, the 2 Wire Cam Sensor Wiring Diagram will show how these two wires connect to the vehicle's electrical system, allowing the vital position data to reach the ECU.

The information provided by the camshaft position sensor is indispensable for several key engine operations. When combined with the crankshaft position sensor (CKP) signal, the ECU can determine not only the engine's speed but also the precise rotational position of the crankshaft and camshafts. This synchronization allows for:

- Precise Fuel Injection: Ensures fuel is injected at the optimal time for each cylinder.

- Accurate Ignition Timing: Controls when the spark plug fires for maximum combustion efficiency.

- Variable Valve Timing (VVT) Control: Adjusts valve timing for improved performance and emissions across different engine loads.

- Sequential Firing Order: Enables the ECU to fire spark plugs and inject fuel in the correct sequence for each cylinder.

A malfunctioning 2-wire camshaft position sensor can lead to a variety of symptoms, including a check engine light, rough idling, poor acceleration, and in severe cases, the engine may not start at all. Understanding the 2 Wire Cam Sensor Wiring Diagram is therefore paramount for diagnosing and rectifying these issues effectively.

To accurately diagnose and repair any issues related to your camshaft position sensor, it is highly recommended that you consult the specific 2 Wire Cam Sensor Wiring Diagram for your vehicle's make, model, and year. This detailed diagram is your best resource.