A 2 Speed Motor Starter Wiring Diagram is a crucial blueprint for electricians and technicians when installing or troubleshooting motors that can operate at two different speeds. This diagram visually represents the electrical connections required to control these multi-speed motors, ensuring they function correctly and safely. Understanding a 2 Speed Motor Starter Wiring Diagram is essential for anyone working with this type of equipment.

What is a 2 Speed Motor Starter Wiring Diagram and How is it Used?

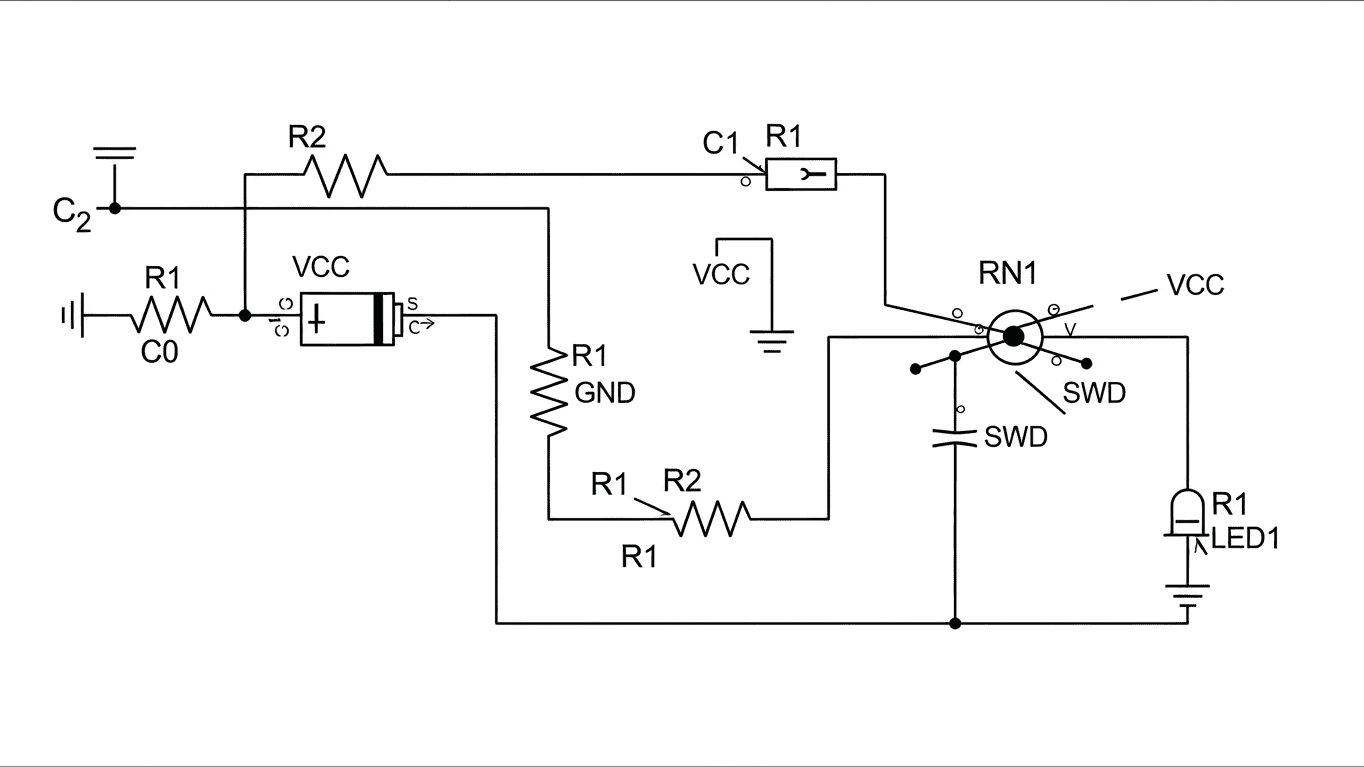

At its core, a 2 Speed Motor Starter Wiring Diagram illustrates the complex network of wires, switches, and components that allow a single motor to achieve two distinct operating speeds. These motors are typically designed with multiple windings or configurations that can be activated to alter their speed. The diagram acts as a guide, showing how power is routed to these different configurations through a starter assembly. This starter assembly often includes contactors or relays that are energized in specific sequences to select either the low-speed or high-speed winding. The accurate interpretation and implementation of this diagram are paramount for the safe and efficient operation of the motor.

The application of 2 Speed Motor Starter Wiring Diagrams is widespread across various industries. They are commonly found in:

- Industrial machinery, such as pumps, fans, and conveyors, where different operational speeds are needed for varying workloads.

- HVAC systems, to adjust airflow and heating/cooling intensity.

- Machine tools, like drills and lathes, to accommodate different material types and machining processes.

The diagram breaks down the control logic into easily understandable electrical pathways. For instance, a typical diagram might show:

- Main power input terminals.

- Control circuits for selecting speed (e.g., a selector switch).

- Contactors or relays responsible for energizing the correct motor windings.

- Overload protection devices to prevent motor damage.

- Connections to the motor itself, indicating which terminals correspond to low and high speeds.

A simplified representation of common components found in such diagrams might look like this:

| Component | Function |

|---|---|

| Selector Switch | User interface to choose between Speed 1 and Speed 2. |

| Contactor (Low Speed) | Energizes the low-speed windings. |

| Contactor (High Speed) | Energizes the high-speed windings. |

| Overload Relay | Protects the motor from excessive current. |

Understanding the symbols and conventions used in a 2 Speed Motor Starter Wiring Diagram is key to correctly wiring the system. Each line and symbol represents a specific electrical connection or component, and deviations from the diagram can lead to malfunction, damage, or safety hazards. Technicians rely heavily on these diagrams to ensure all connections are made in the correct sequence and to troubleshoot issues that may arise. The diagram is not just a drawing; it's a critical operational manual for the electrical control of a two-speed motor.

To gain a comprehensive understanding and ensure you are referencing the correct schematic for your specific motor and starter, please refer to the detailed diagrams provided in the manufacturer's installation manual for your particular model.